The Essential Role of Fatliquoring in Leather Making

The fat liquoring or lubricating step in leather making has the primary purpose of preventing the fibre structure from sticking during drying after completion of wet processing steps.

The secondary effect is to confer softness. It gives effective lubricationensuring leather can exhibit the maximum strength allowed by processing and material.

Lubrication is typically achieved through self-emulsifying properties of oils, natural or synthetic, which have been partially sulphated or sulphited. The sulpho fraction is the emulsifier carrier in aqueous solution of the neutral oil, which is the active agent in the lubricating mechanism.

A complimentary process is to confer water resistance to leather. Traditional and recent methods gave results that were erratic at best, but modern chemistriesbased on partially esterified acrylate polymers and or siliconeare effective and consistent.

Lubrication of the leather is done often using partially sulphated or sulfonated oils, which may be anial, vegetable or mineral in origin.

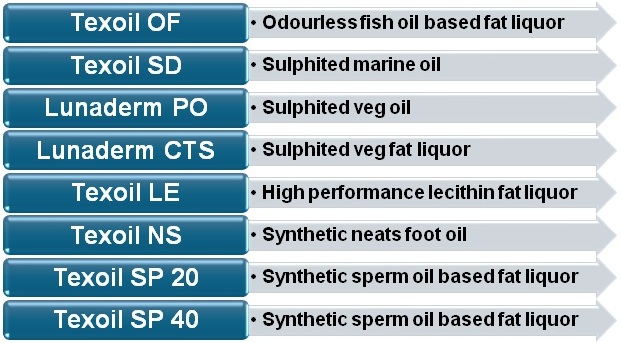

Types of Fat Liquors

Natural Oils consists of Animal Oils, Marine Oils and Vegetable Oils.

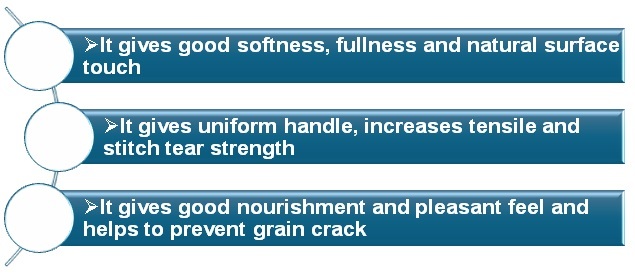

Properties

Synthetic Oils

Cationic Fat Liquor

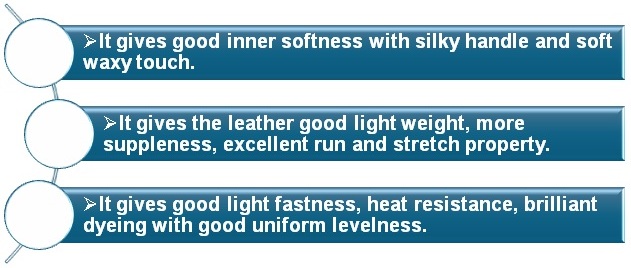

Properties

Dosage is recommended based on the articles to be made like shoe uppers, upholstery, travel bags, hand bags, industrial gloves, golf gloves, garments, harness saddler, industrial tool leathers, chamois leathers and automobile leather.

AvailablePacking

50 or 120 or 200 kg HDPE Drums

Conclusion

Leather fatliquors are essential in leather manufacturing process providing numerous benefits that enhance the quality, appearance and durability of leather products. Understanding the role and types of fatliquors can help customer appreciate the value of high-quality leather articles.

Tex Biosciences manufactures a full range of high quality fat liquors to enhance customer satisfaction at all times. All products that we manufacture for Leather Applications are REACH Compliant and ZDHC.

We are an ISO 9001, ISO 22000, FAMI QS and ZDHC Certified Organization and meet European standards. All our products and processes are strictly monitored, controlled and continuously improved. We employ an ERP system where all Finished Products are tested and only if the product quality is approved by Quality Control, can the product be billed and dispatched to customers.

We are able to offer customized products based on market conditions and customer requirements. Please do get in touch with us for your specific requirements.

For more details or trade inquiries on the product, please contact us at info@texbiosciences.com